NEW PRODUCT RELEASE

Recently Released Components and Technology Solutions from Progressive.

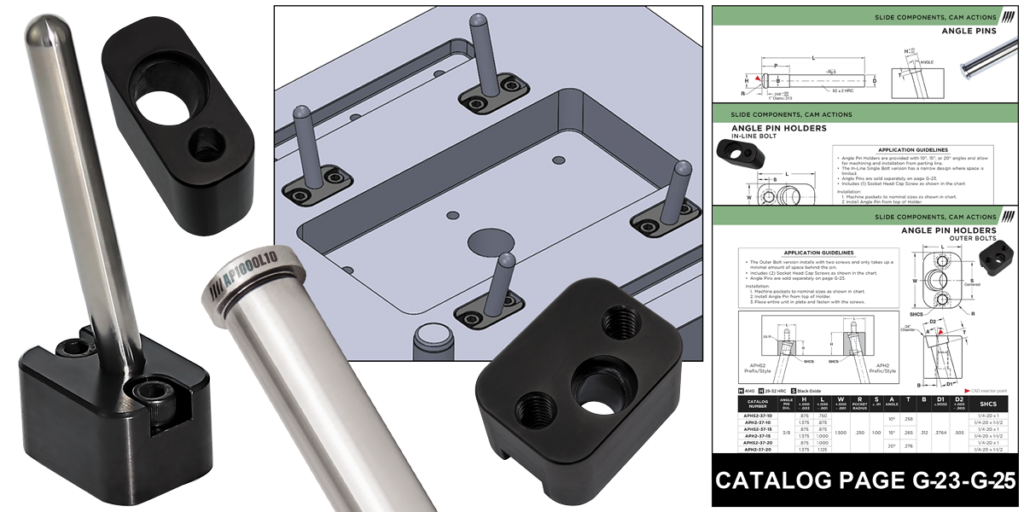

ANGLE PINS & ANGLE PIN HOLDERS

Designed to simplify the installation of Angle Pins, Progressive’s Angle Pin Holder conveniently installs and can be removed from the parting line, accommodating Progressive’s standard Angle Pins without any additional machining required. Available in In-Line Bolt and Dual Bolt styles with machined 10°, 15°, or 20° angled holes. New, for larger tools, are 1″ diameter Angle Pins, and six new 1″ Angle Pin Holders.

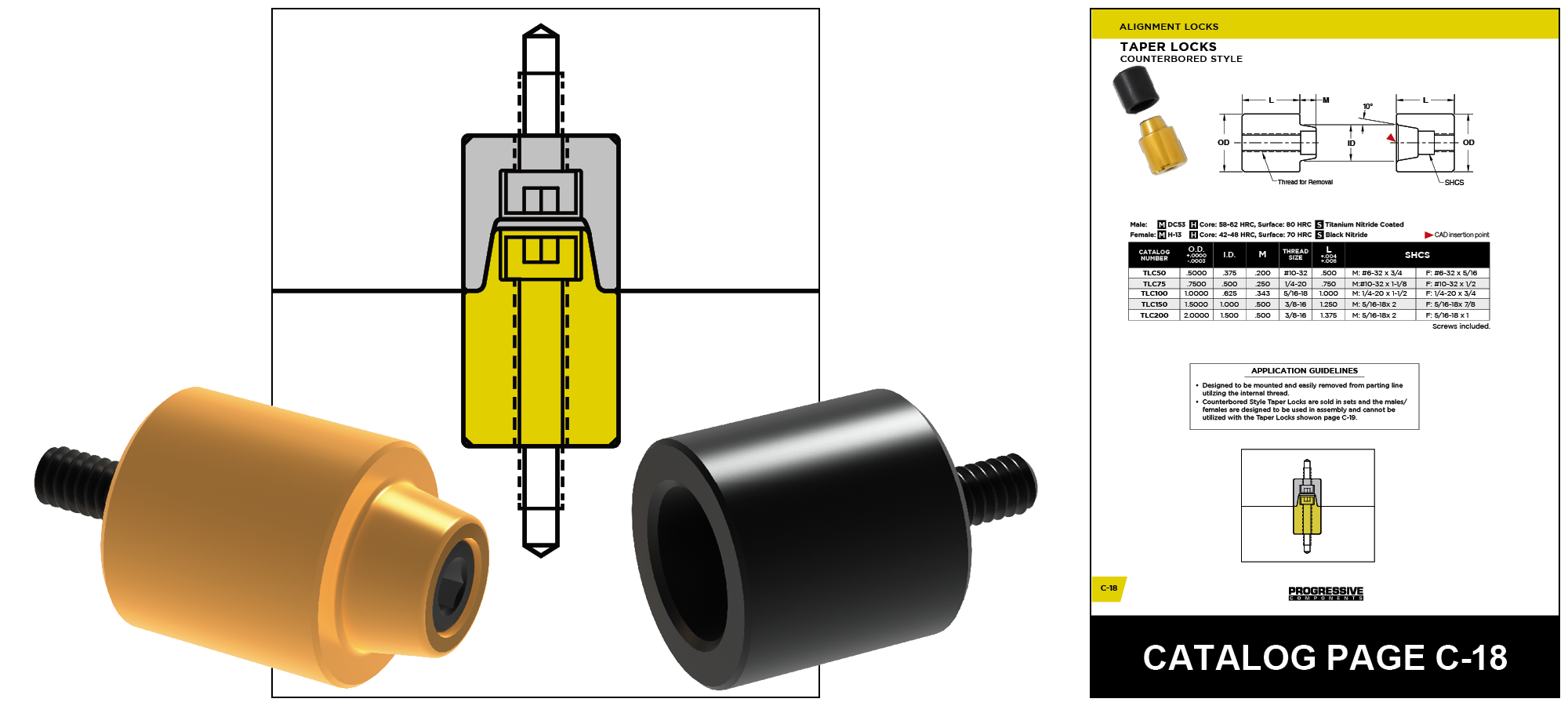

COUNTERBORED ROUND TAPER LOCKS

Mounted from the mold’s parting line, the new Counterbored Round Taper Lock is available in a range of five sizes from 1/2” to 2” diameters. This advanced standard is the industry’s only Taper Lock featuring Progressive’s proprietary materials and treatments.

Click HERE for additional information and online ordering.

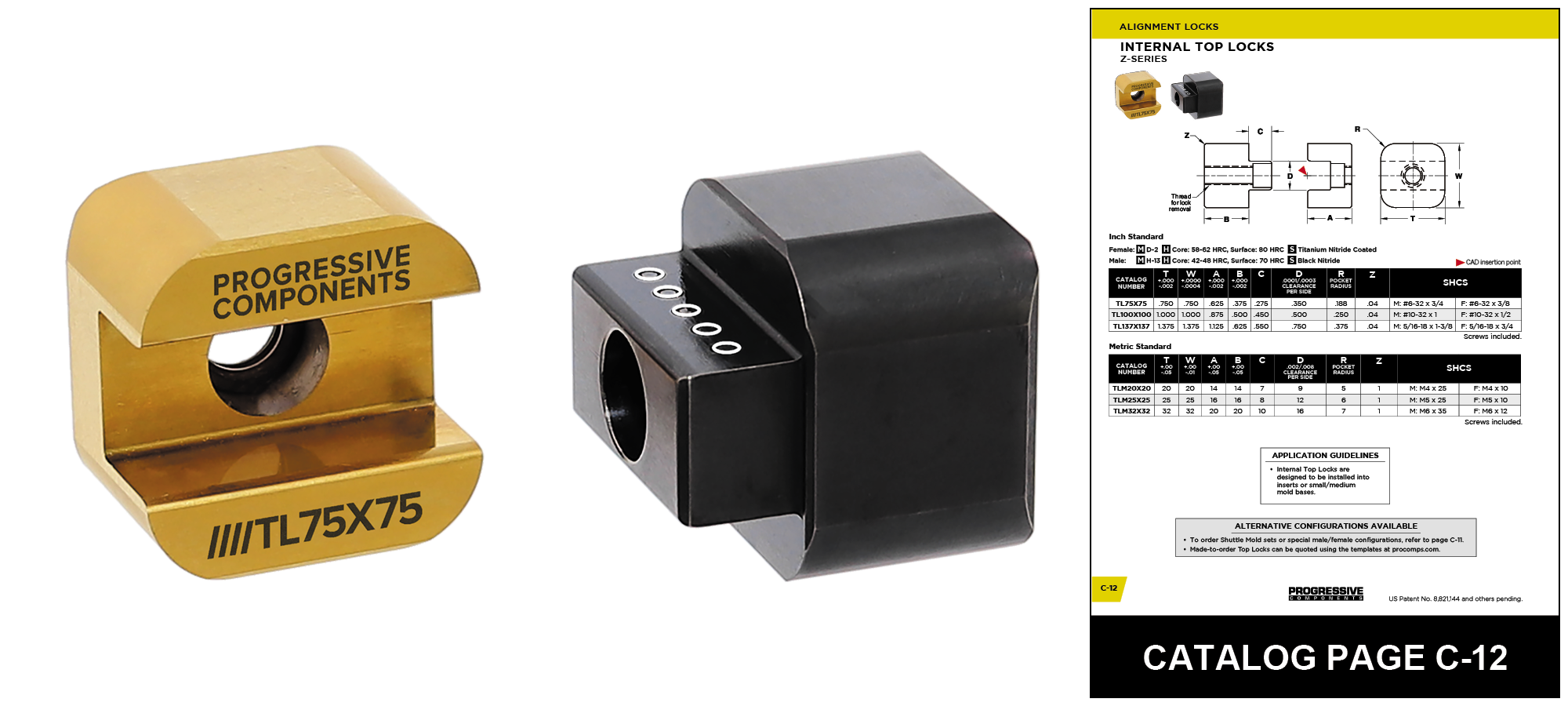

INTERNAL TOP LOCKS

To avoid water lines and other mold features, the new square Internal Top Lock mounts inboard versus at the mold base’s edge and are available in three inch and three metric sizes to provide maximum alignment with minimal space requirements.

Click HERE for additional information and online ordering.

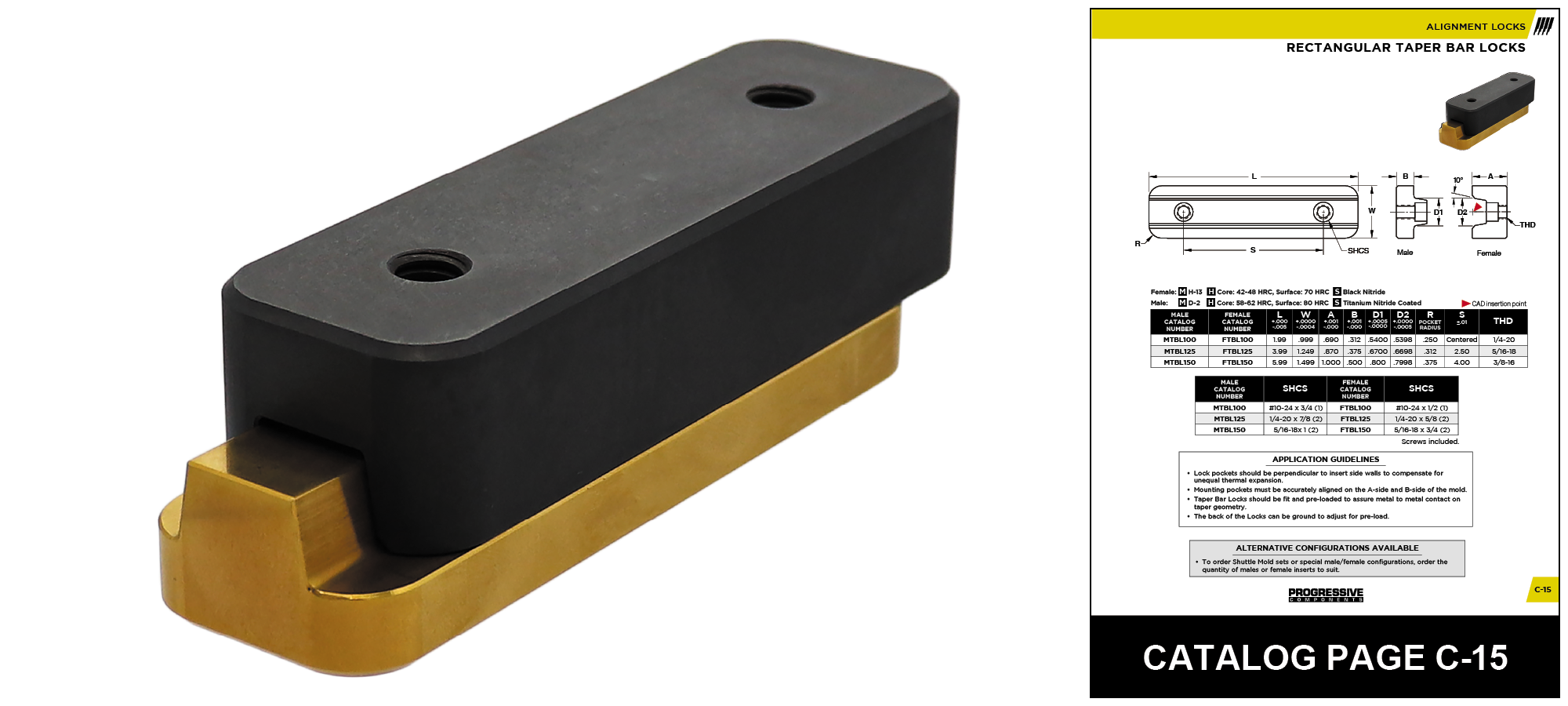

RECTANGULAR TAPER BAR LOCKS

Engineered to be installed and removed from the parting line, the new Rectangular Taper Bar Lock provides precision alignment with an increased alignment surface. Sizes offered match industry standards, but performance is maximized through the utilization of Progressive’s Z-Series materials and treatments.

Click HERE for additional information and online ordering.

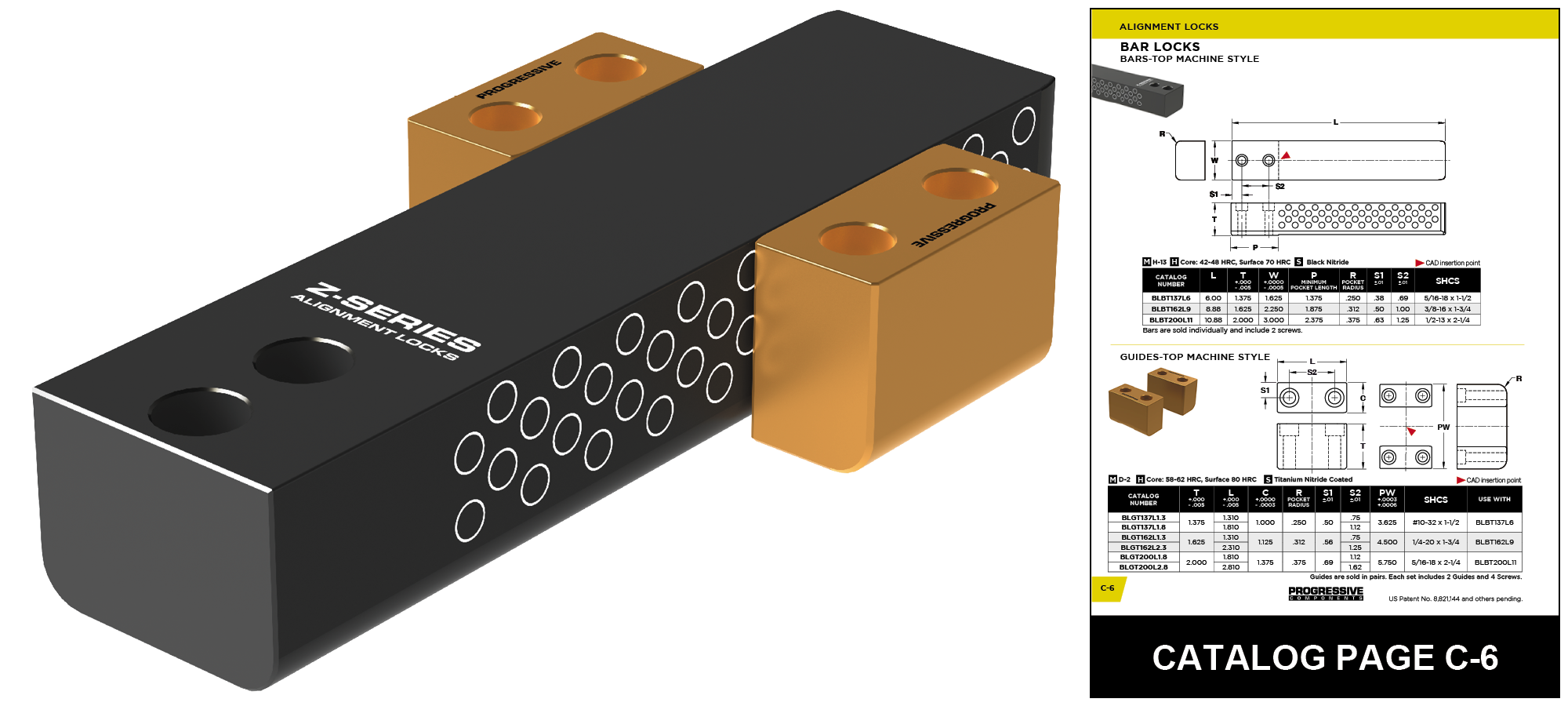

TOP MACHINE STYLE BAR LOCKS

Designed to be machined from the top at the parting line, Top Machine Bar Locks simplify machining steps and increase pocket accuracy by allowing the alignment pockets to be machined on the same setup as cavity and core plate pockets. Top Machine Bars are available in three sizes to

pair with corresponding Guides.

Click HERE for additional information and online ordering.

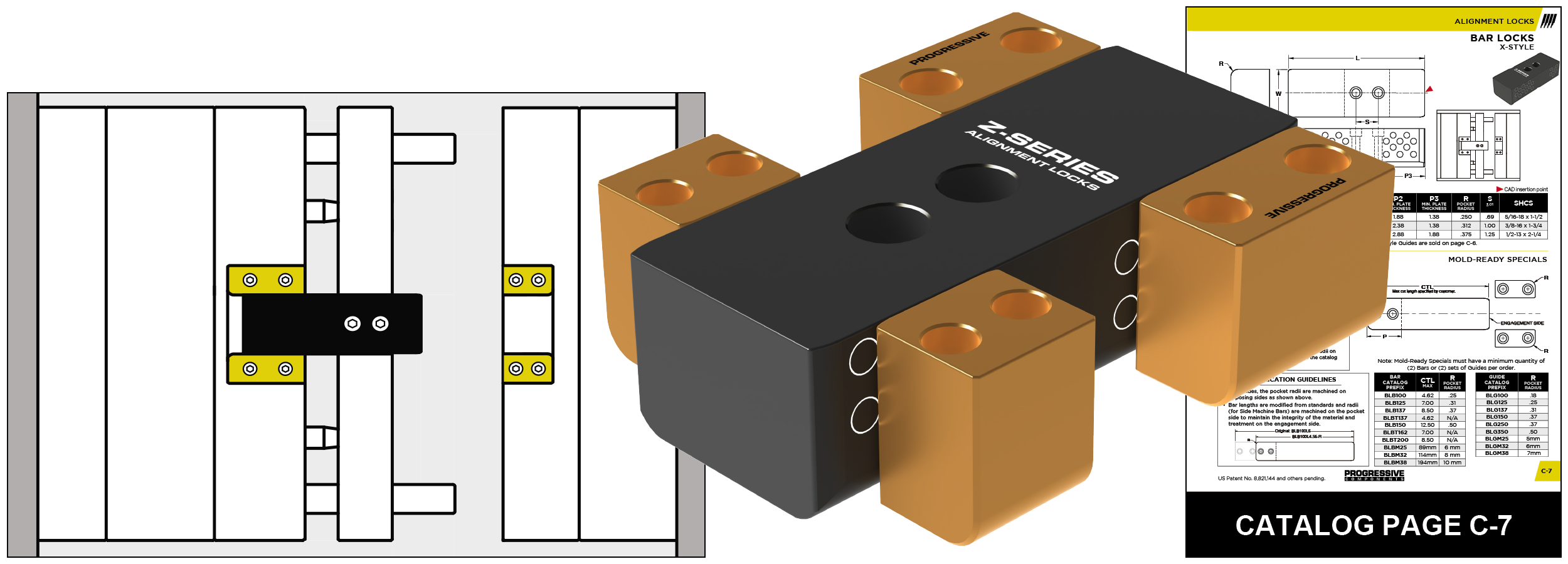

X-STYLE BAR LOCKS

For multi-parting line tools, Progressive has added an X-Style Bar Lock configuration. X-Style Bars are available in three sizes to pair with corresponding Guides.

Click HERE for additional information and online ordering.

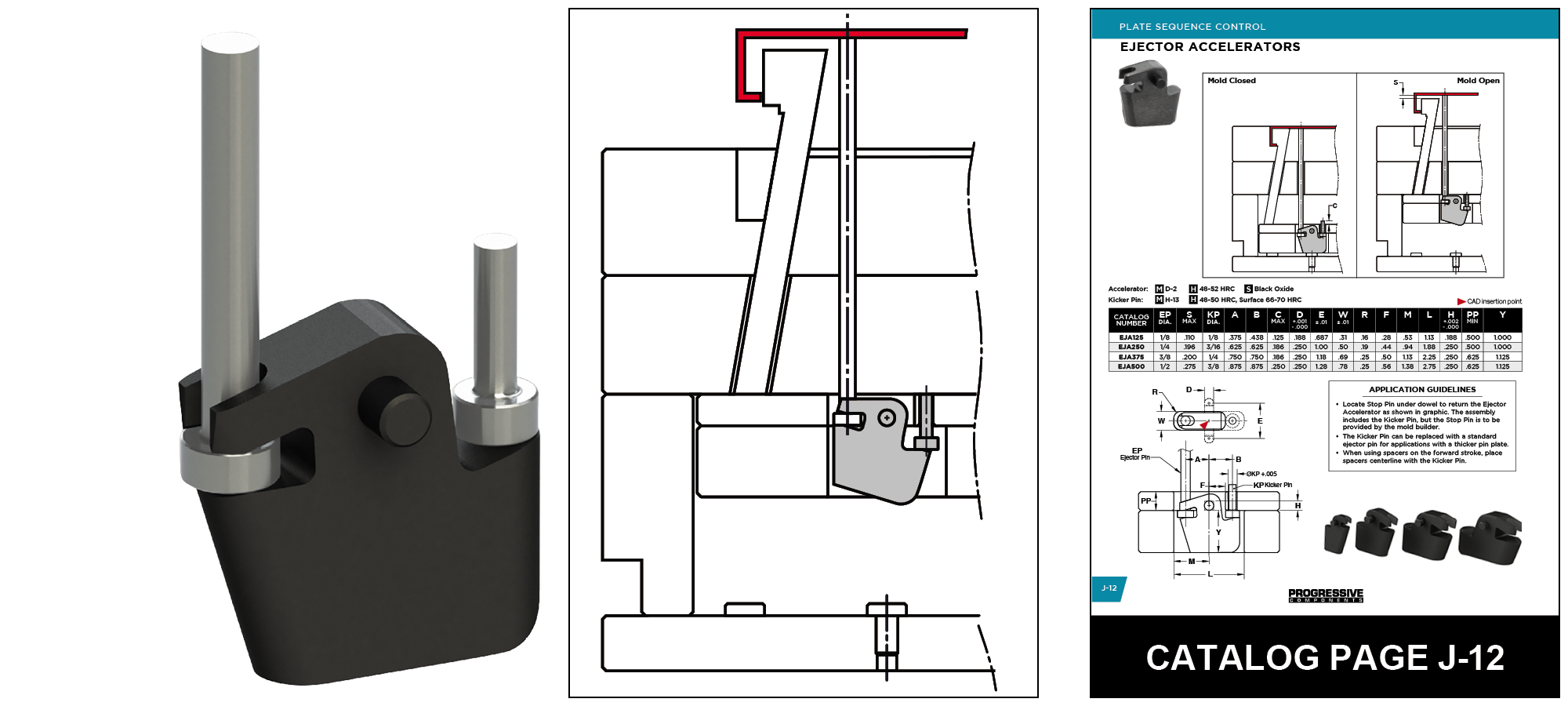

EJECTOR ACCELERATORS

Featuring a compact footprint and sized for inch ejector pins and ejector plates, Ejector Accelerators create a second-stage ejection without the need for a second set of ejector plates. They are designed to actuate an ejector pin forward when additional pin travel is required to release the molded part from lifters, stripper plates, or deep core features, are available in four standard-inch sizes and include a kicker pin and dowel pin installed.

Click HERE for additional information and online ordering.

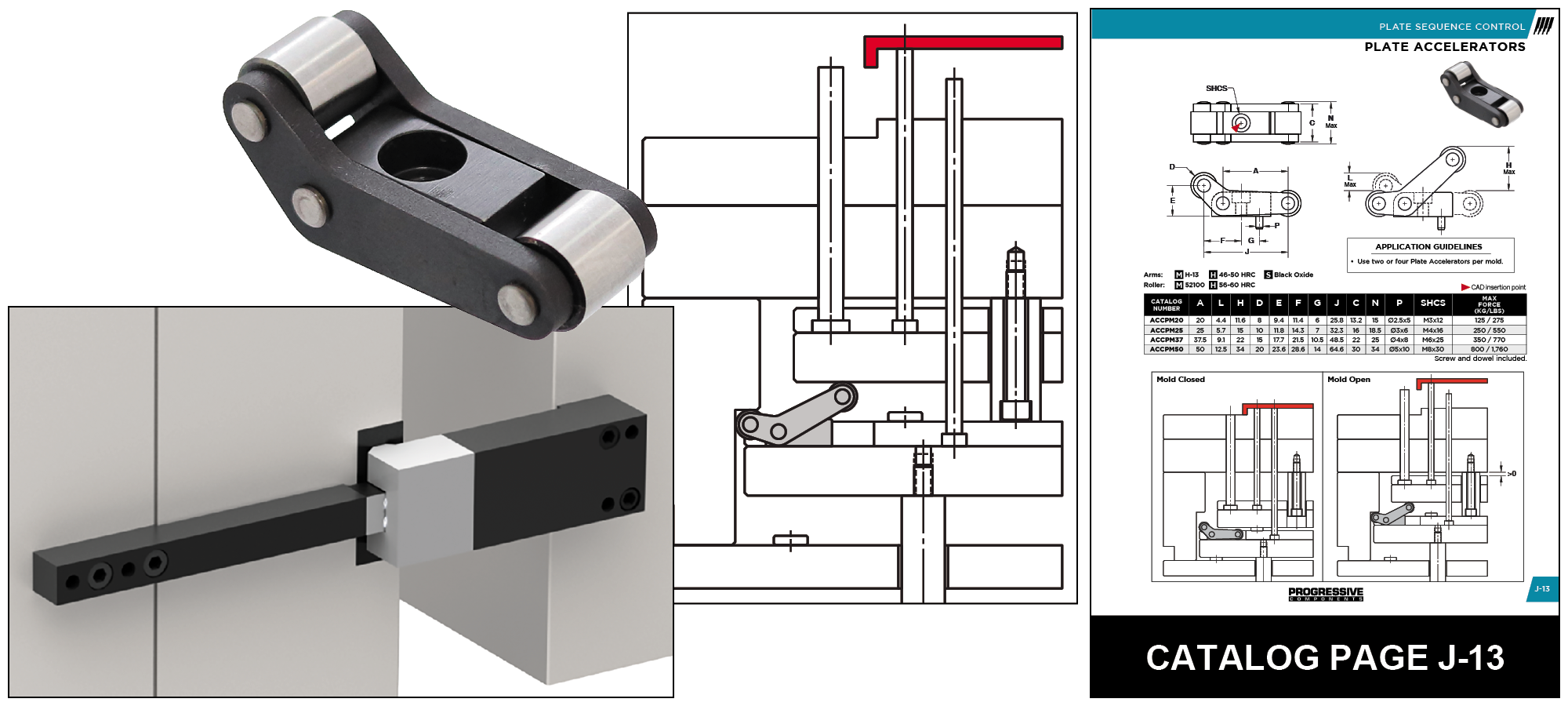

NEW PLATE SEQUENCING OPTIONS

To further build out Pro’s Plate Sequence Control program, new rocker-style Plate Accelerators have been added for double ejection applications, along with additional sizes of Latch Locks for large multi-parting line tools.

Click HERE for additional information and online ordering.

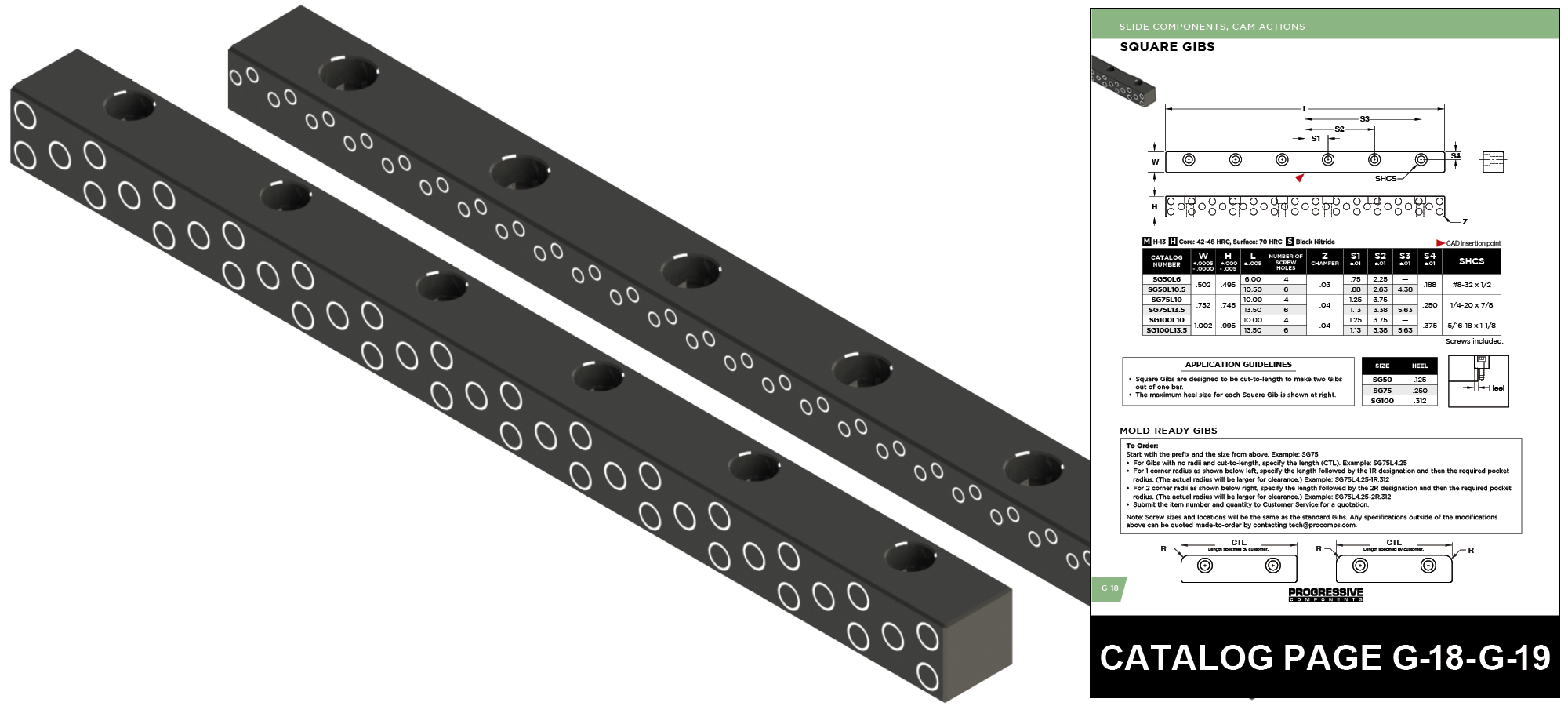

SQUARE GIBS AND CENTER GUIDES

Available off-the-shelf with pre-machined counterbores for SHCS, new Square Gibs and Center Guides are designed to be cut-to-length for each slide’s required length. Offered in six standard sizes providing a range of lengths from 2” to 13.5” long, Progressive’s Gibs and Guides feature Pro’s Z-Series Black Nitride finish for greaseless performance.

Click HERE for additional information and online ordering.

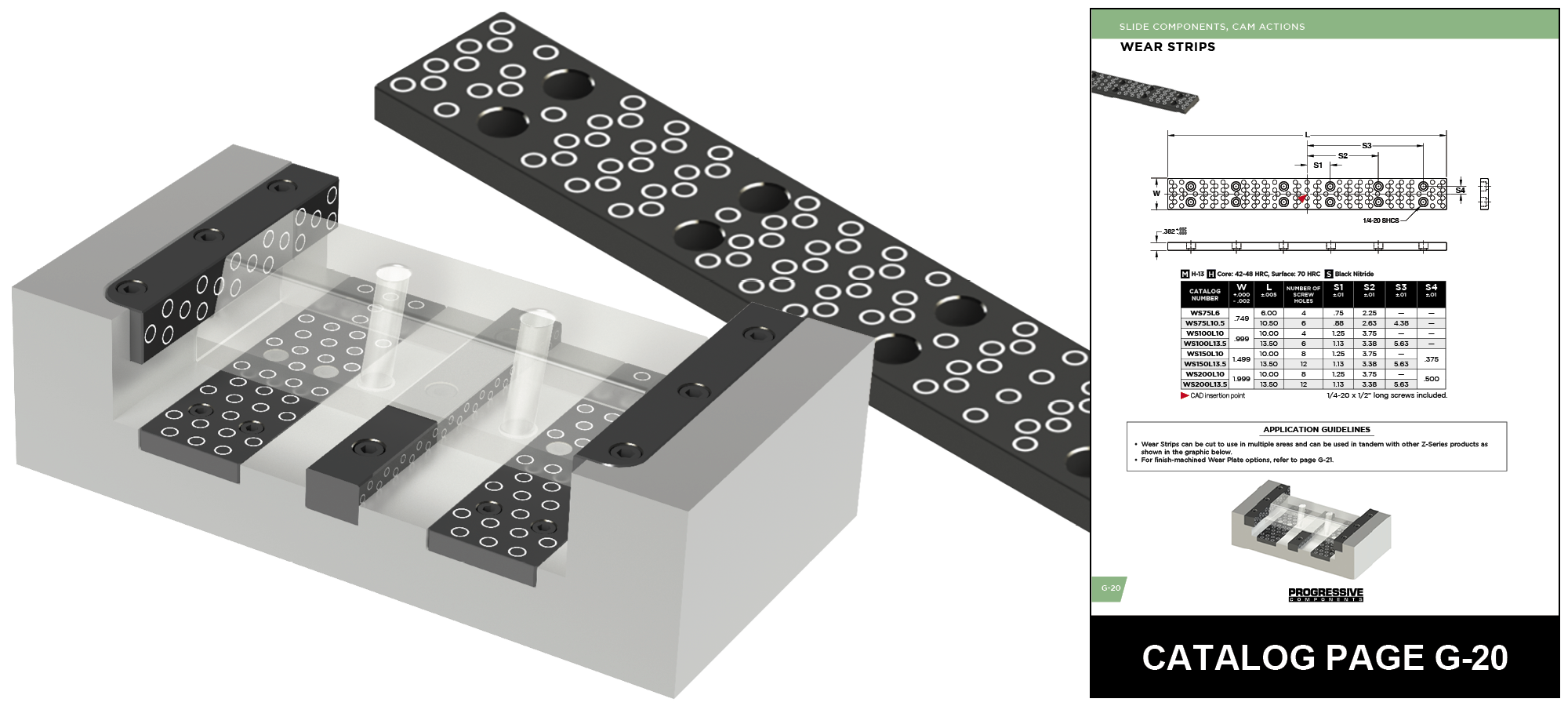

WEAR STRIPS

Wear Strips offer a time-saving approach for side action applications, needing only to be cut to the slide’s finished length required. Provided

flat and including final fitting stock, Pro’s Wear Strips are easy to grind when compared to others’ bronze-plated steel or aluminum bronze wear plates and offer Pro’s Black Nitride for proven greaseless performance.

Click HERE for additional information and online ordering.

MOLD MONITORING ADVANCEMENTS

ProFile® Real-Time Monitoring and Asset Management now offers a more robust product with new features scalable to suit the needs of any organization. OEMs, Molders, and Mold Builders can now access one cloud-based program to monitor, maintain, manage, and track their tooling fleet and equipment, and a newly designed interface allows for various levels of visibility to help optimize production and maximize efficiencies.

Click HERE for more information.

UNILIFTER: C-SERIES

Designed to self-compensate when a mold’s ejector plates become misaligned, the C-Series UniLifter® offers simplified installation with Pro’s “click-in-place assembly” feature. Assembly detents allow toolmakers to set the Core Blade, C-Coupling, and C-Gib to the correct angle and position, enabling easy assembly into the mold pocket without parts sliding out of place.

Also new are hardened S-7 Core Blades.

For more info, testing data, and customer testimonials, click HERE.

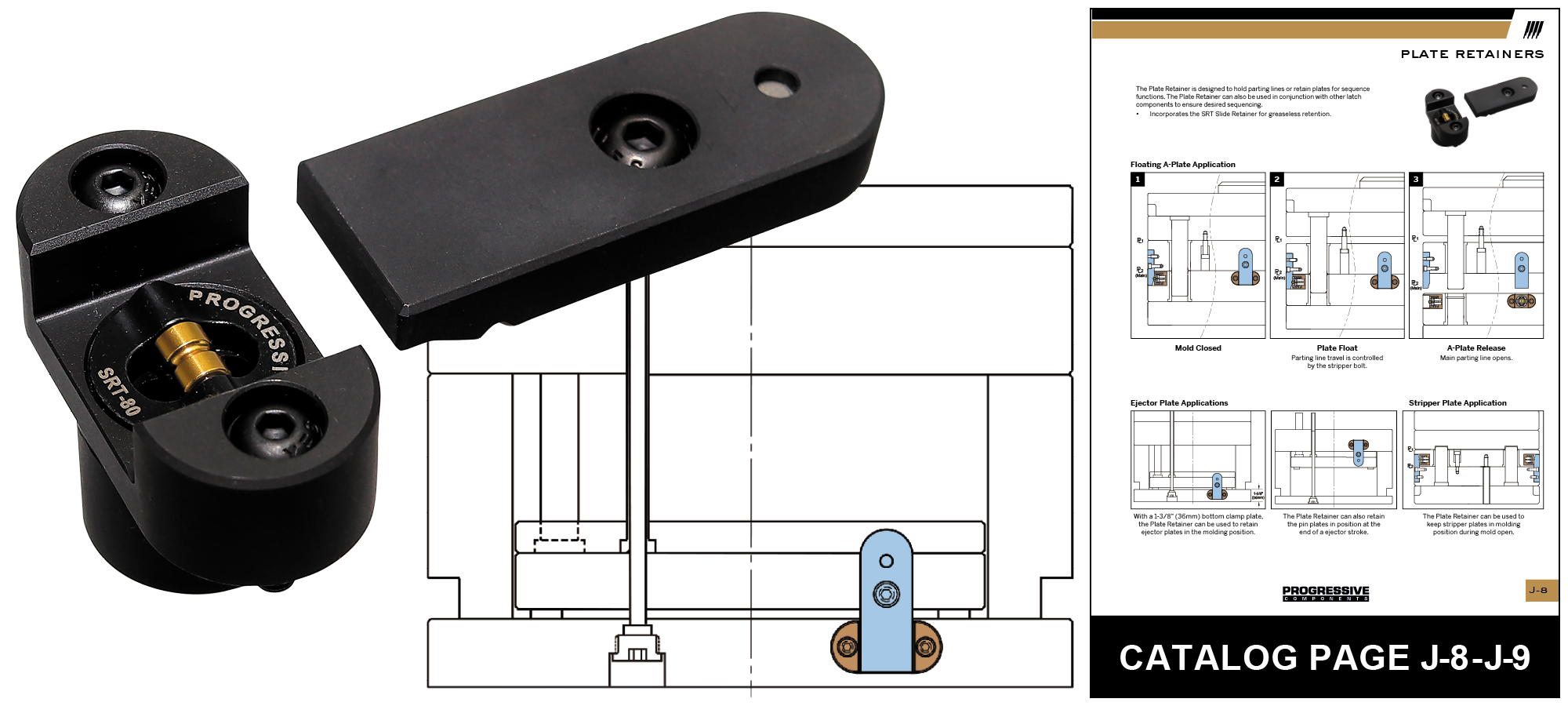

PLATE RETAINERS

Compact design over alternative methods, Progressive’s new Plate Retainer is engineered to hold parting lines or retain plates for sequence functions and incorporates the SRT Slide Retainer for greaseless retention. Dissimilar steels and treatments provide superior wear resistance during production and require simple pocket machining for Bar and Housing.

Click HERE for additional information and online ordering.

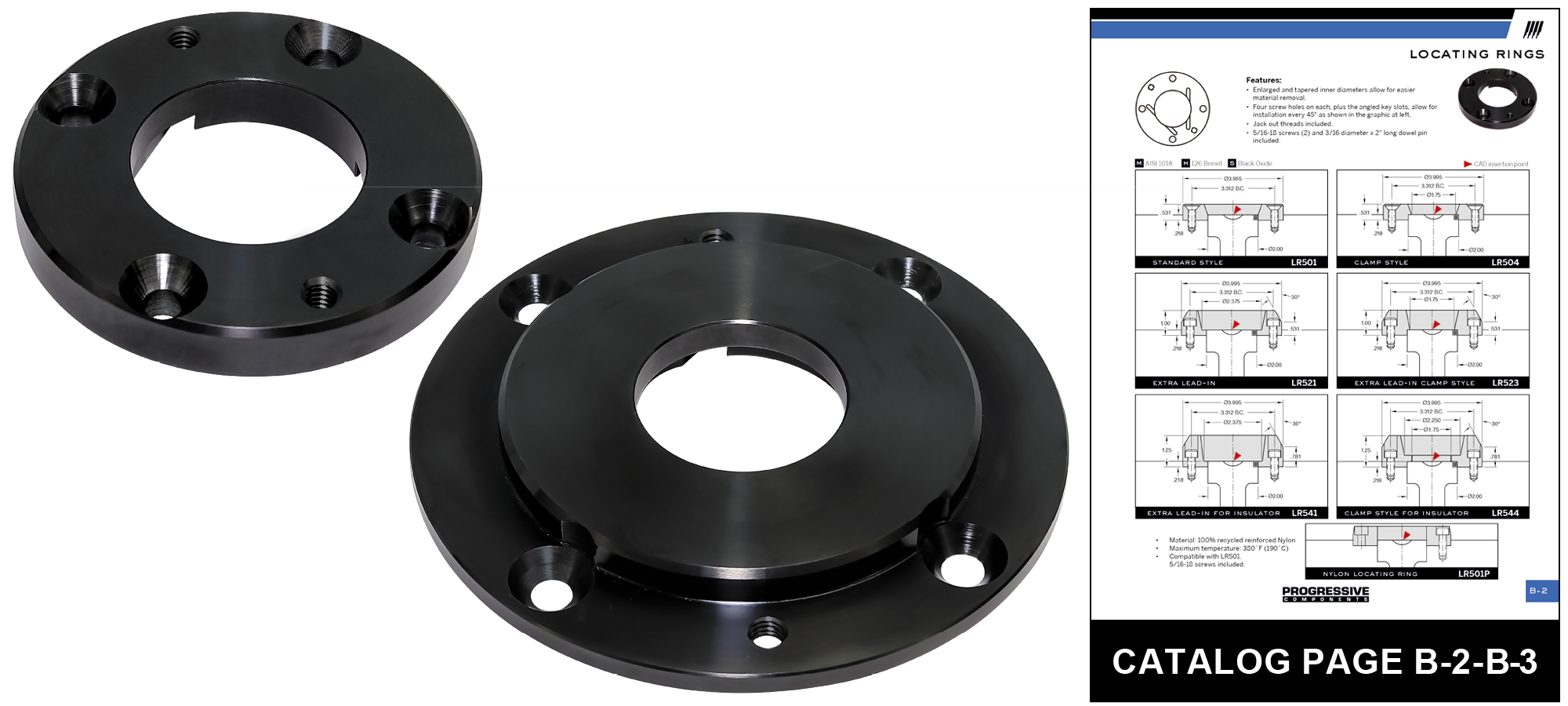

LOCATING RINGS

BLACK NITRIDE GUIDED EJECTOR BUSHINGS

Progressive has added Black Nitride Guided Ejector Bushings to our line of Black Nitride products as a standard, off-the-shelf item. Available in sizes from 1/2″ diameter to 2″ diameter, these Black Nitride Guided Ejector Bushings are proven to provide improved performance in greaseless medical environments and are durable enough for Die Casters.

Click HERE for additional information and online ordering.

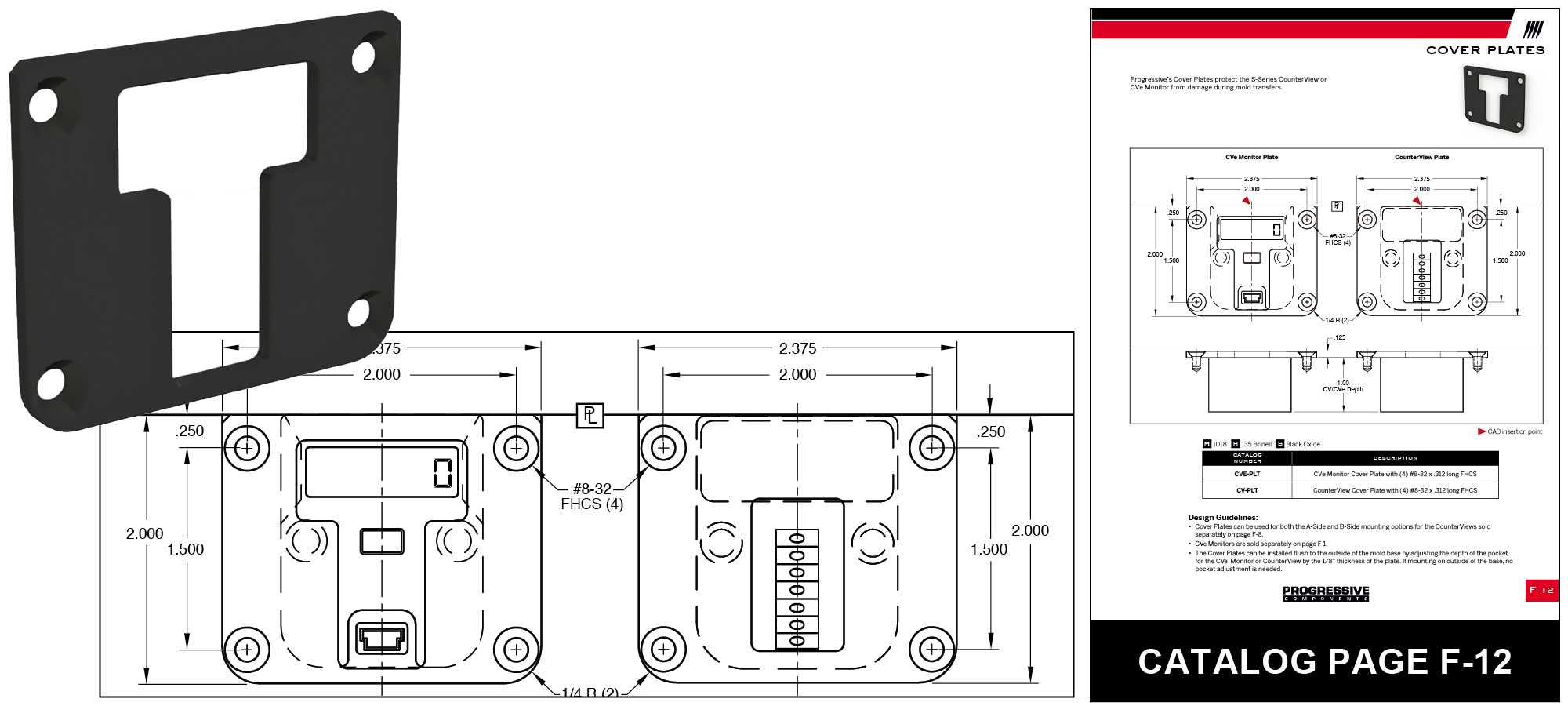

COVER PLATES

To protect Progressive’s CVe Monitors or CounterViews from damage during mold transfers, new Cover Plates are now available. Designed for easy installation, the Cover Plate allows for full visibility of the CounterView cycle counts or display and button on the CVe Monitor.

Click HERE for additional information and online ordering.

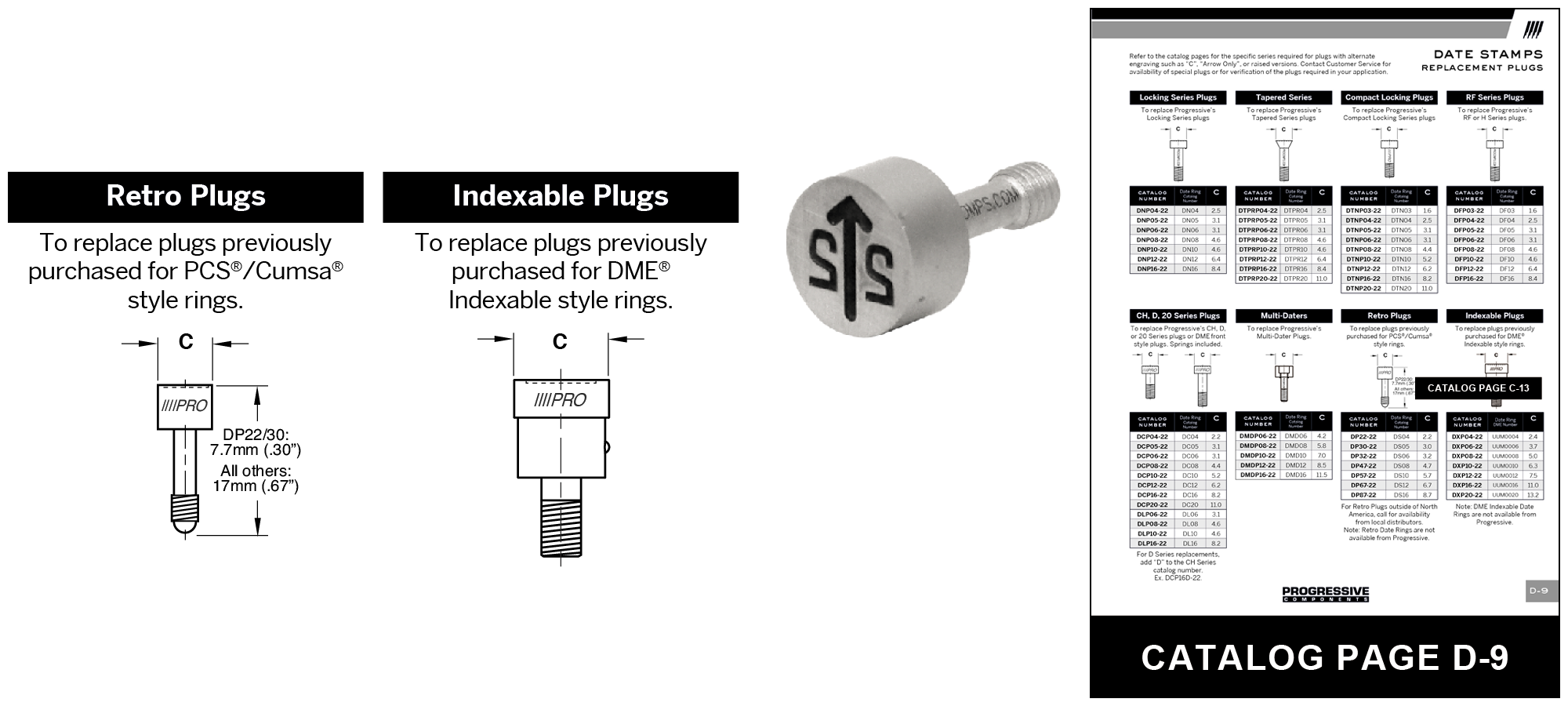

REPLACEMENT DATE PLUGS

New sizes of Retro Plugs (replacements for previously purchased PCS/Cumsa style rings) have been added for 4mm and 5mm rings, and a new line of Indexable Plugs (to replace plugs previously purchased for DME Indexable style rings) has been added with sizes ranging from 4mm to 20mm.

Click HERE for additional information and online ordering.

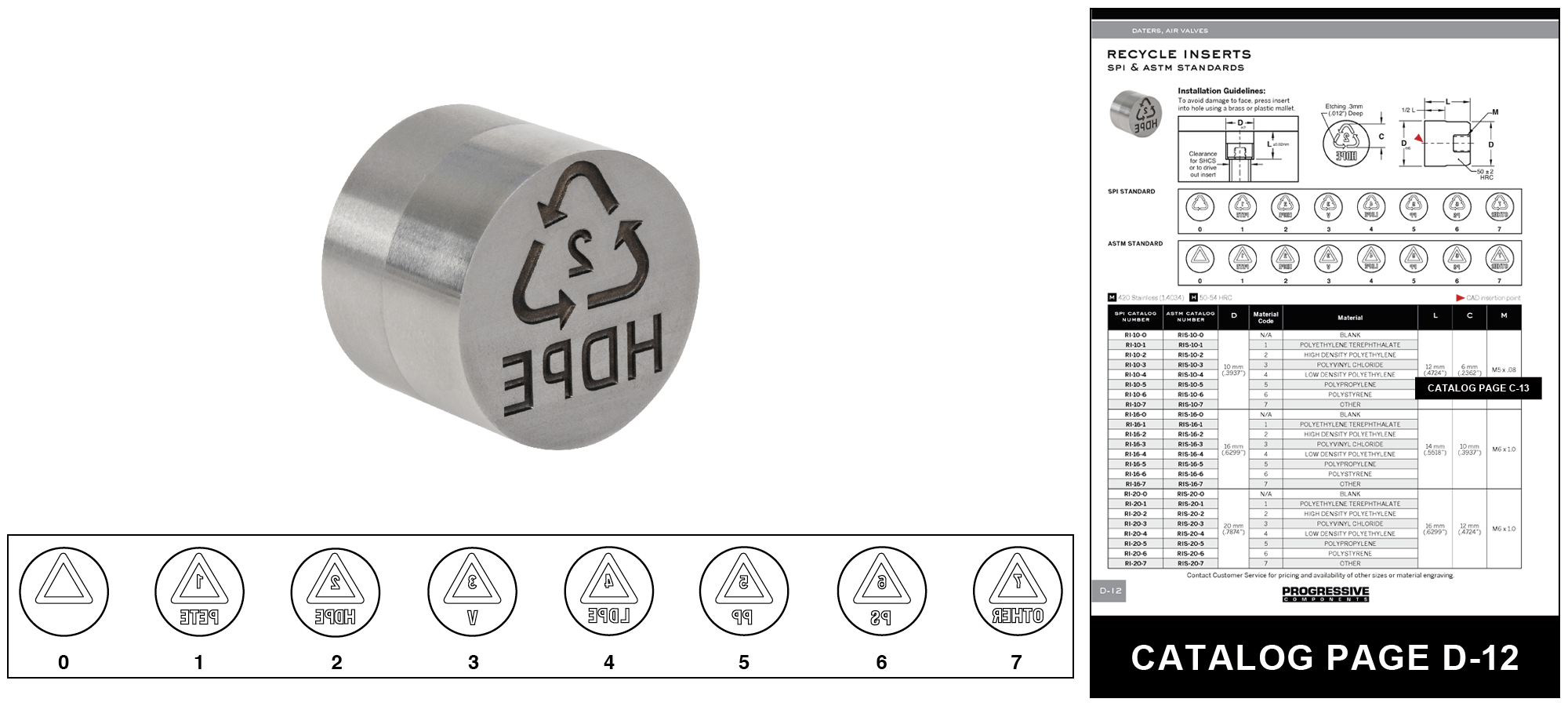

RECYCLE INSERTS

Increasing our offering of Recycle Inserts Pro has added a new line that follows the ASTM (American Society for Testing & Materials) standards.

Click HERE for additional information and online ordering.

METRIC AIR POPPETS

Expanding our line of Air Poppets, Progressive has added new metric standard sizes ranging from 6mm to 16mm in diameter to allow customers the ability to design them into their metric tools.

Click HERE for additional information and online ordering.

RHINOFEET: ELIMINATE A SHOP HAZARD

Through an alliance with Rhino Visions, Progressive now offers the RhinoFoot product line to eliminate the hazards associated with placing molds and plates on wood blocks and pallets. RhinoFeet™ and RhinoToes™ provide a working load of 7,000 lbs and are each sold in packages of four.

Click HERE for additional information.

NOZZLE TIPS, NOZZLE CADDIE, & WRENCH

Progressive now offers a new, patented Nozzle Tip featuring heat sinking fins to eliminate mold damaging stringing. To keep Nozzle Tips within reach, the new Nozzle Caddie magnetically mounts to the molding press. And, because removing and installing nozzle tips can be a real ‘knuckle buster,’ our new Offset Slugging Wrench is the preferred tool for mold setup personnel.

Click HERE for additional information.

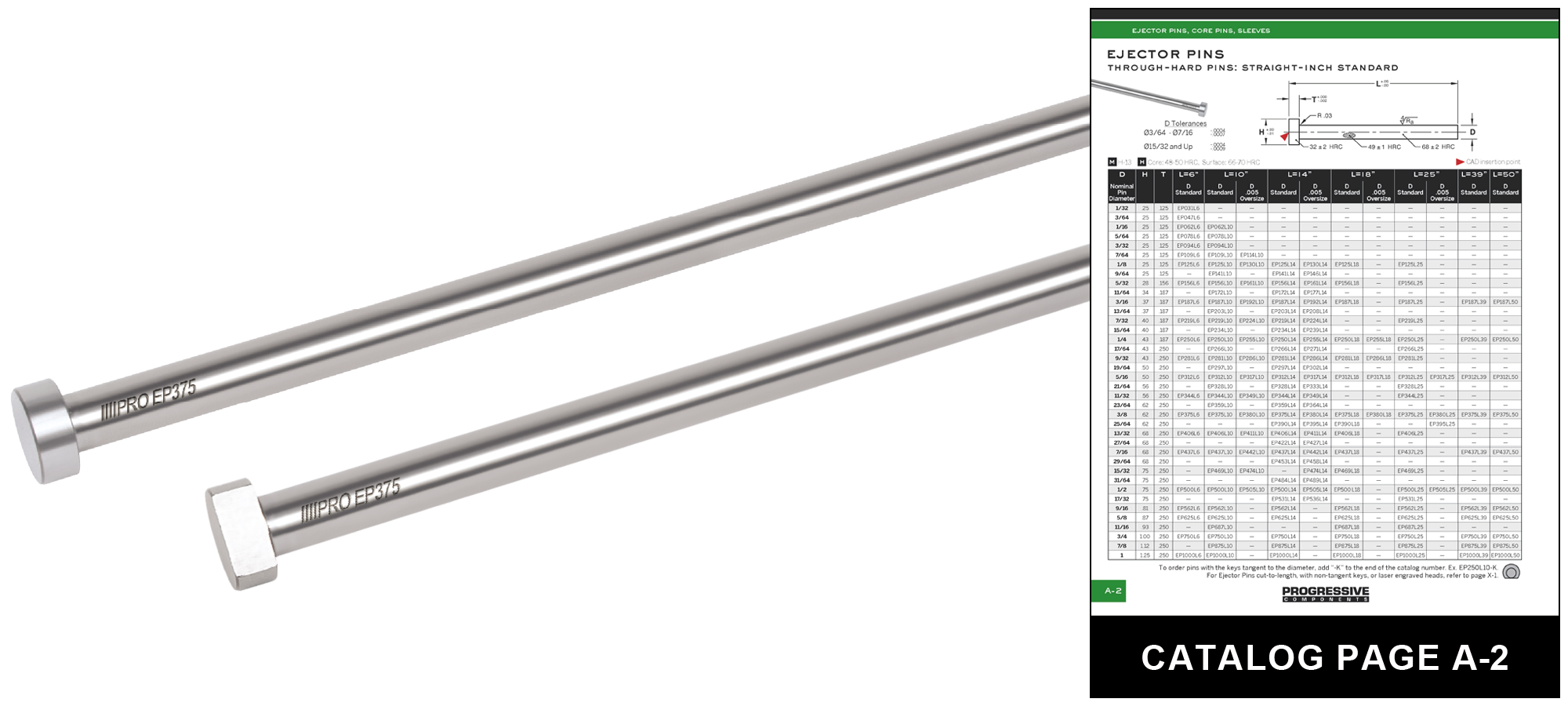

THROUGH-HARD EJECTOR PINS

Progressive’s through-hard Ejector Pins offer consistent quality and sizing, feature a micro-finish, 66-70 HRC surface to reduce hole wear and damage, and a 48-50 HRC core hardness to prevent dishing, nicking, and chipping. Sizes range from 1/32” diameter to larger diameters in 50” lengths.

For more info, testing data, and customer testimonials, click HERE.

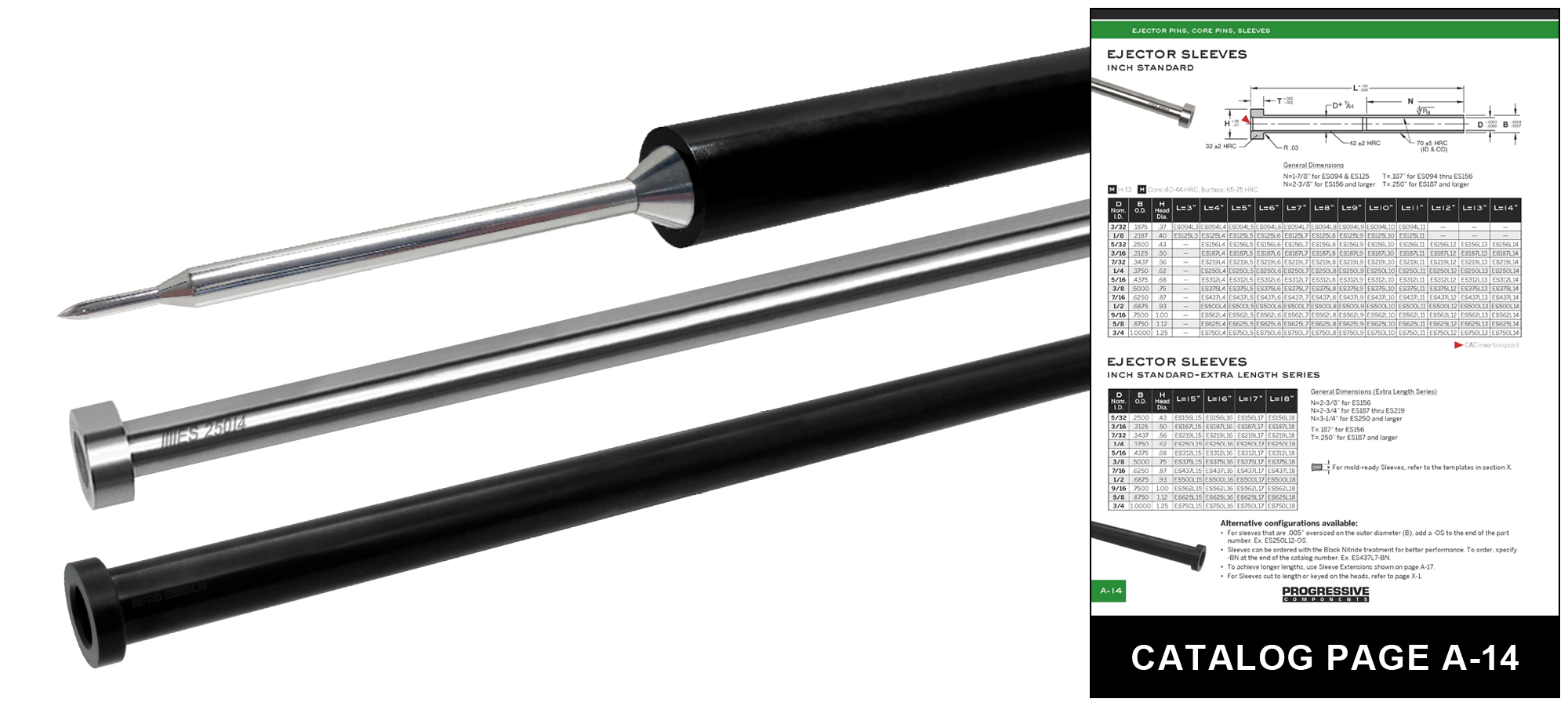

EJECTOR SLEEVES: LONGER LENGTHS

Progressive has added 300 new sizes to its range of H-13 Ejector Sleeves. Where U.S. standards end at 14” lengths, we now offer off-the-shelf sizes in 15”, 16”, 17”, and 18”. Also added are new Black Nitride Sleeves, which feature a precision honed lubricious surface that does not require grease in cleanroom applications, and a high hardness (66-70 HRC) suited for the harsh conditions of die casting.

Click HERE to view our recent press release.

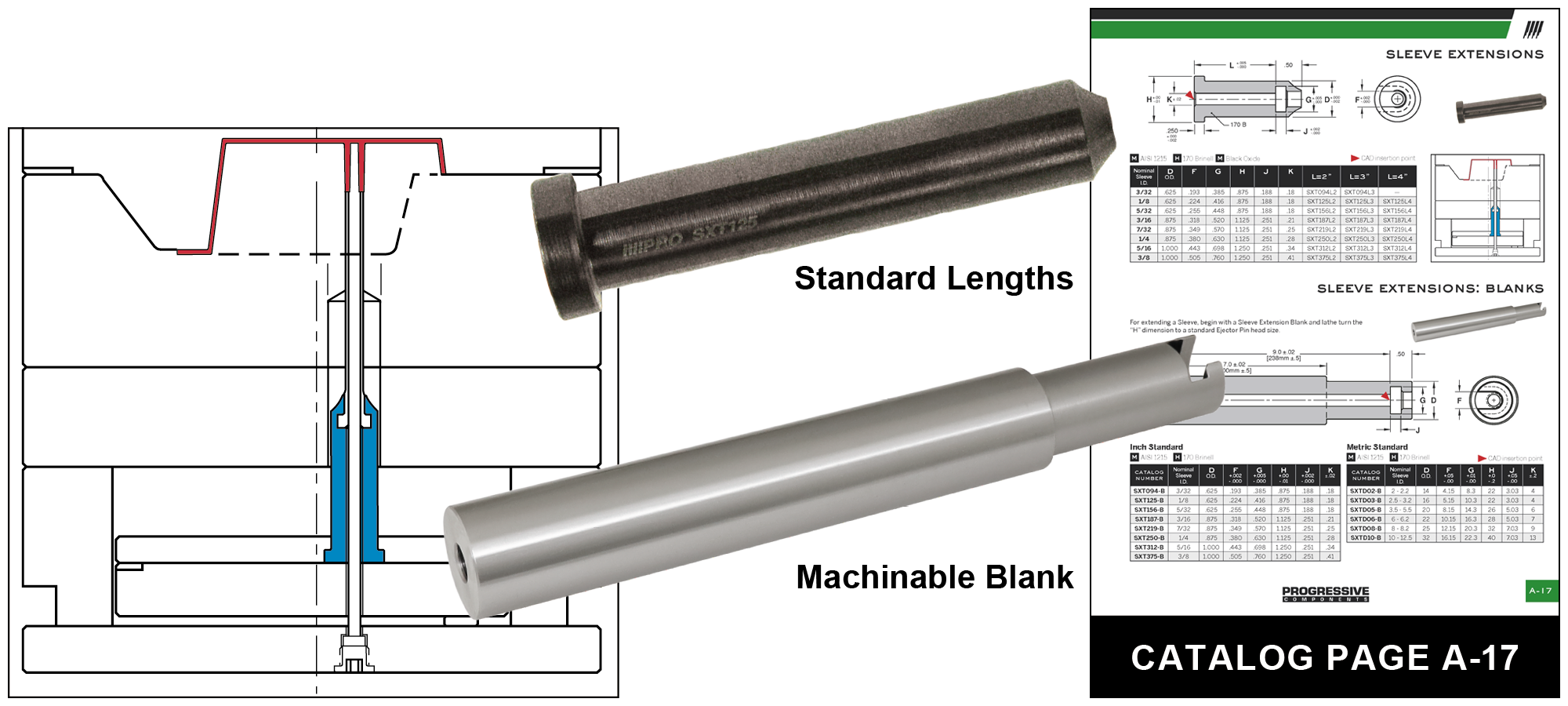

SLEEVE EXTENSIONS: NEW SIZES & OPTIONS

New sizes of Sleeve Extensions are now available in 2” and 4” lengths. Also added is the new Sleeve Extension Blank (available in inch and metric options), allowing customers to extend their sleeves further.

Click HERE to view our recent press release.

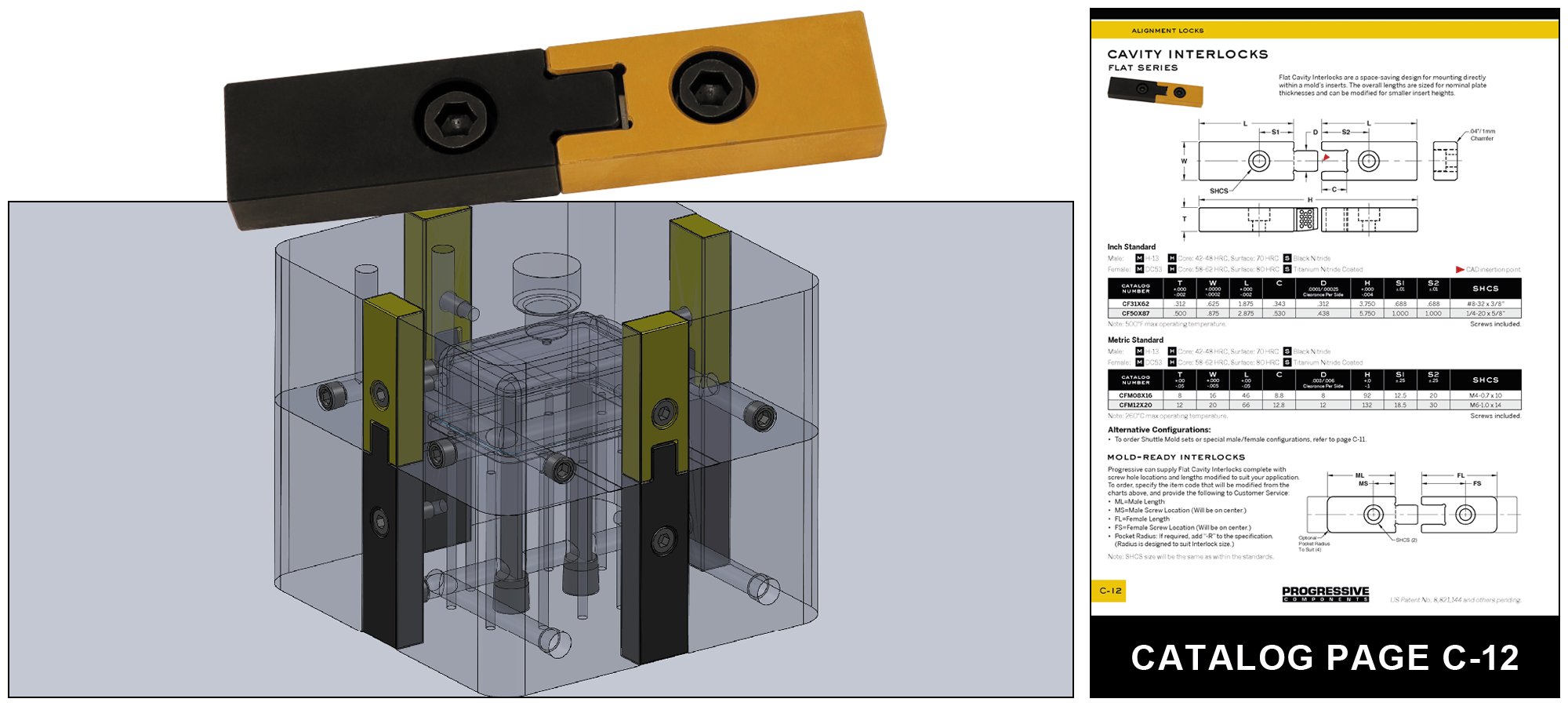

CAVITY INTERLOCKS: FLAT SERIES

Progressive’s new Flat Cavity Interlocks are a space-saving design for mounting directly within a mold’s inserts. Overall lengths are sized for nominal plate thicknesses beginning at widths of only .625”, and lengths can be modified to suit the height of cavity and core inserts.

Click HERE to view our recent press release.

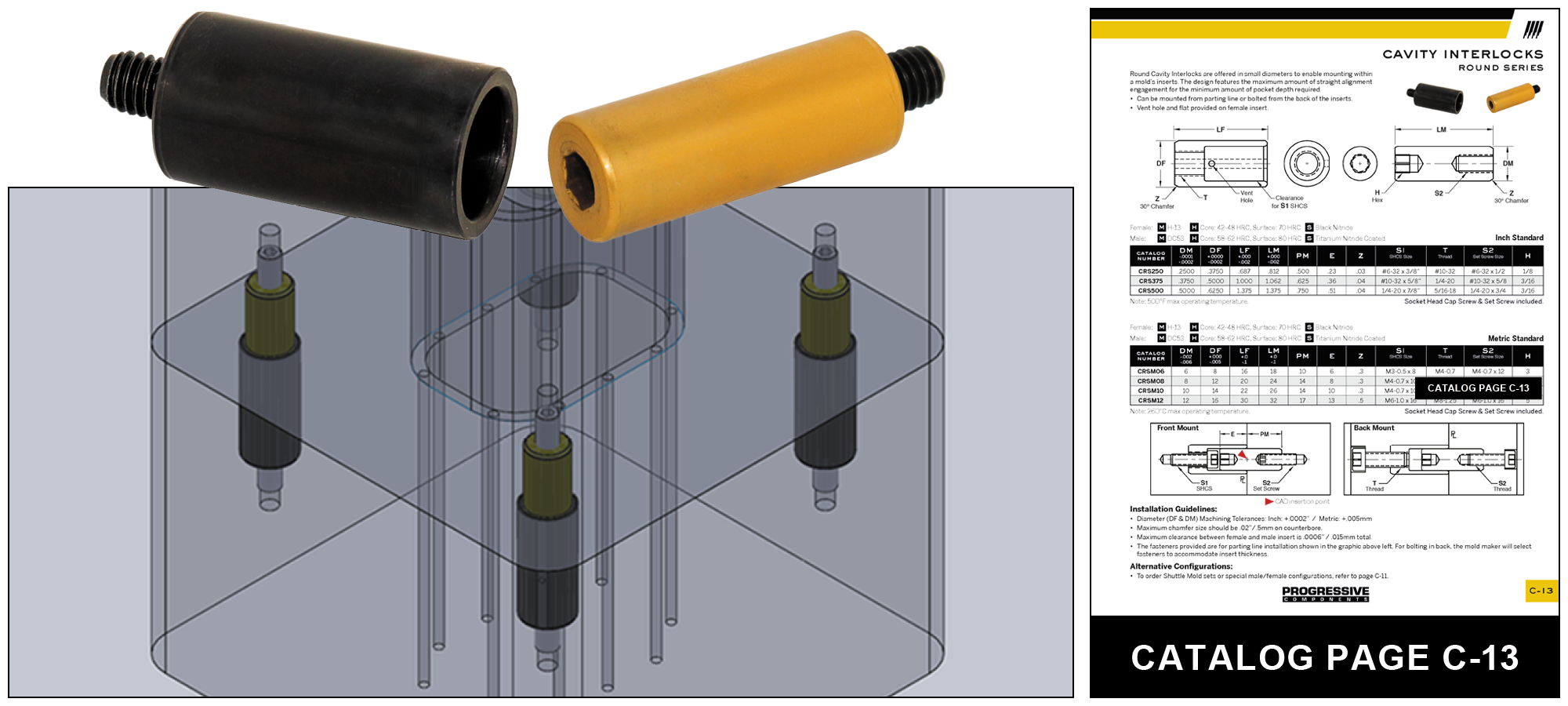

CAVITY INTERLOCKS: ROUND SERIES

The new Round Cavity Interlocks, designed to mount within a mold’s insert, feature the maximum amount of straight alignment engagement for the minimum amount of pocket depth required. Available in three diameters (1/4”, 3/8”, 1/2”), they can mount from the parting line to enable details such as waterlines to be located underneath or bolted from the back of the insert.

Click HERE to view our recent press release.

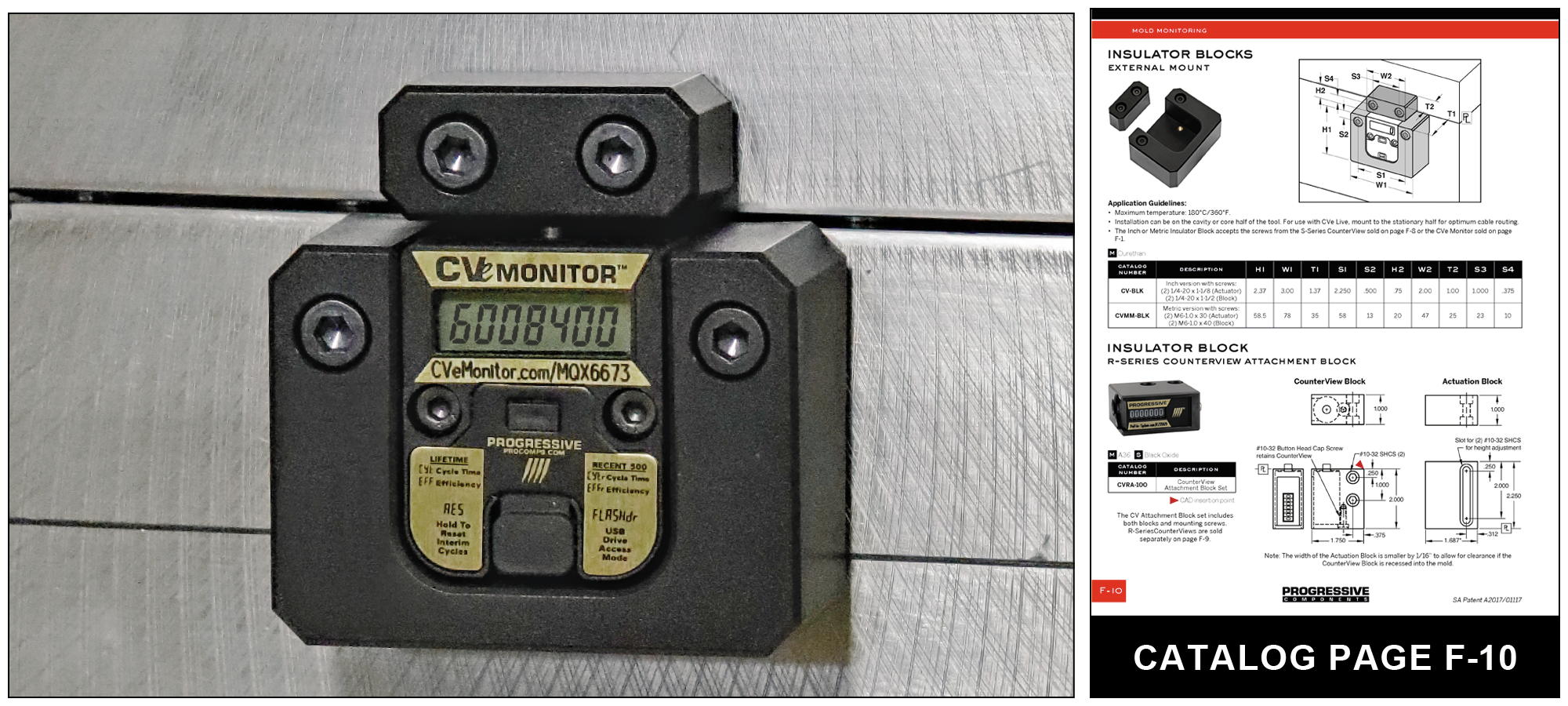

COUNTERS FOR EITHER MOLD HALF

The new industry exclusive S-Series CounterView can be viewed from the operator side when mounted on the stationary half / A side of the mold.

Click HERE for animations, testing data, customer testimonials, and more.

COUNTERVIEW: HIGH TEMPERATURE

The new High Temp CounterView offers the same functionality as Pro’s standard cycle counter with the added benefit of sustainability in higher temperature tools operating at a maximum of 375° F (190°C). Additionally, Progressive’s CounterViews can be ordered pre-set to a specific cycle count for direct replacement.

Click HERE for animations, testing data, customer testimonials, and more.

INSULATOR BLOCK: EXTERNAL MOUNT

Designed to protect the CVe Monitor and CounterView when molding high-temperature resins, the exclusive External mount Insulator Block allows Progressive’s monitoring devices to perform at mold temps up to 360°F (180°C). Installation can occur on the cavity or core half of the tool. When using CVe live, mounting is recommended on the stationary half for optimum cable routing.

Click HERE for additional information.

INSULATOR BLOCK: RETROFIT BRACKET

Insulator Blocks protect Progressive’s monitoring devices in high heat applications. The new Retrofit Bracket installs within an existing pocket without any modification to the mold’s cavity or core half, allowing the CVe Monitor or CounterView to perform at temps up to 410°F (210°C). The CVe Monitor and CounterView are actuated via a Striker, which is attached to the Insulator Bracket as a single unit. No preload adjustment is required.

Click HERE to view our recent press release.

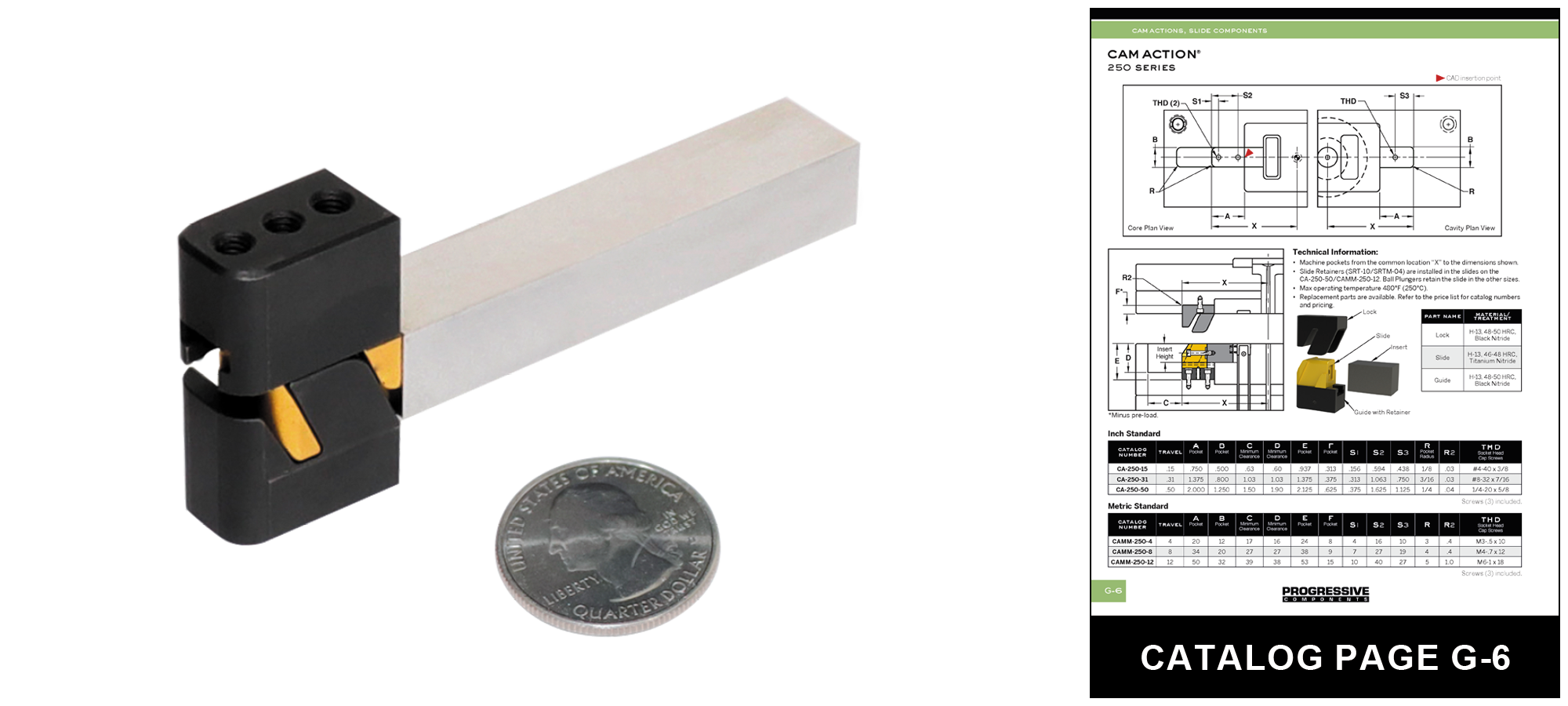

CAMACTIONS™

A new series of CamActions are now available with a smaller footprint and travel distances ranging from .15” to .50”. Inserts are available in two different materials based on machining preferences.

Click HERE to view our product animation.

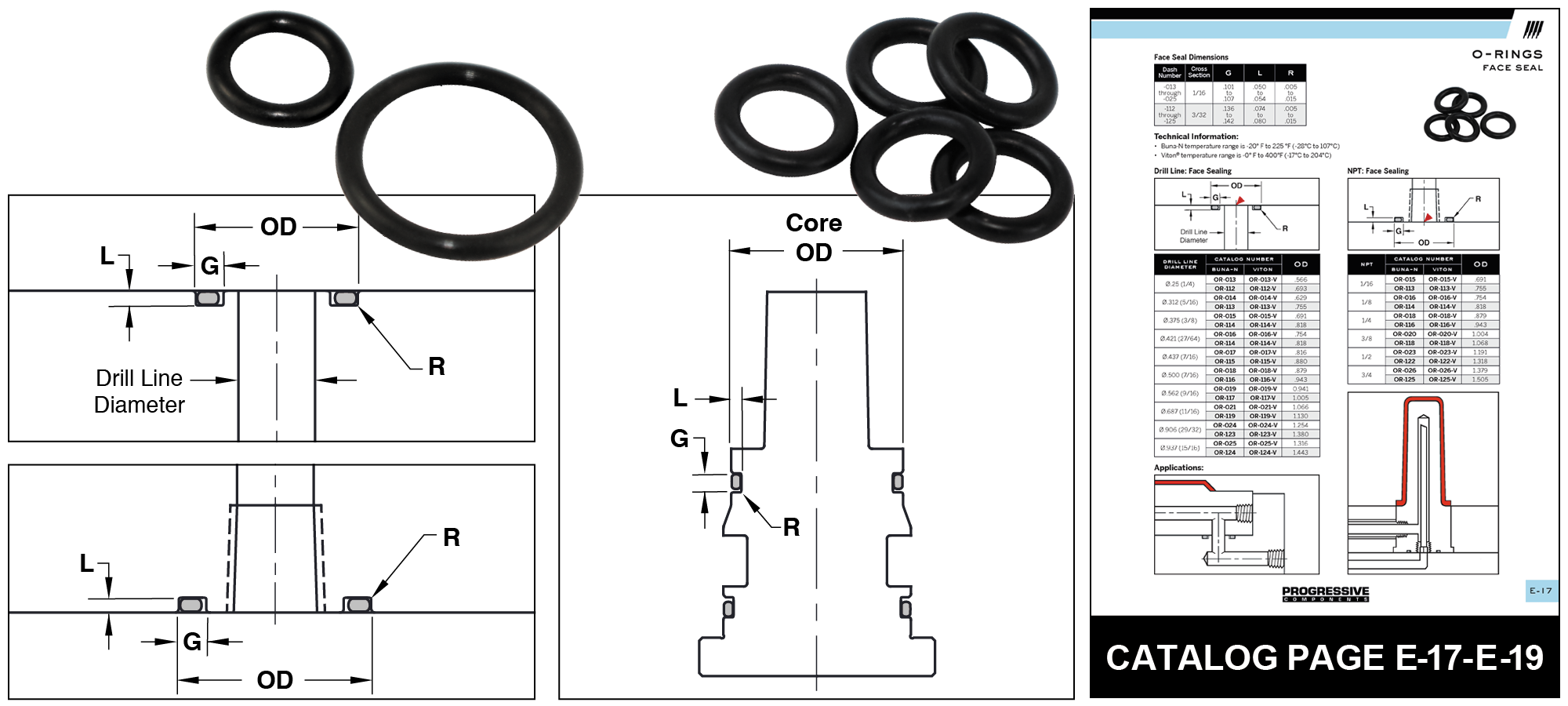

O-RINGS

Progressive’s addition of O-Rings provides designers with CAD geometry that includes the machine groove detail and makes replacement downstream easier for mold maintenance personnel. O-Rings are available in two material options: Buna-N for temps up to 225° F, and Viton for temps up to 400° F.

Click HERE to view our recent press release.

LOCKING SOCKET CONNECTORS

Locking Socket Connectors provide a positive locking connection to Extension or Connector Plugs. Connect and twist to lock the sleeve into place. To order, specify -L as the suffix to the standard items in the chart on page E-25. Examples: SC205-L (Standard Barbs), SC300B-L (Body), and SC326-PL-L (Push-Lok Barbs).

Click HERE for additional information.

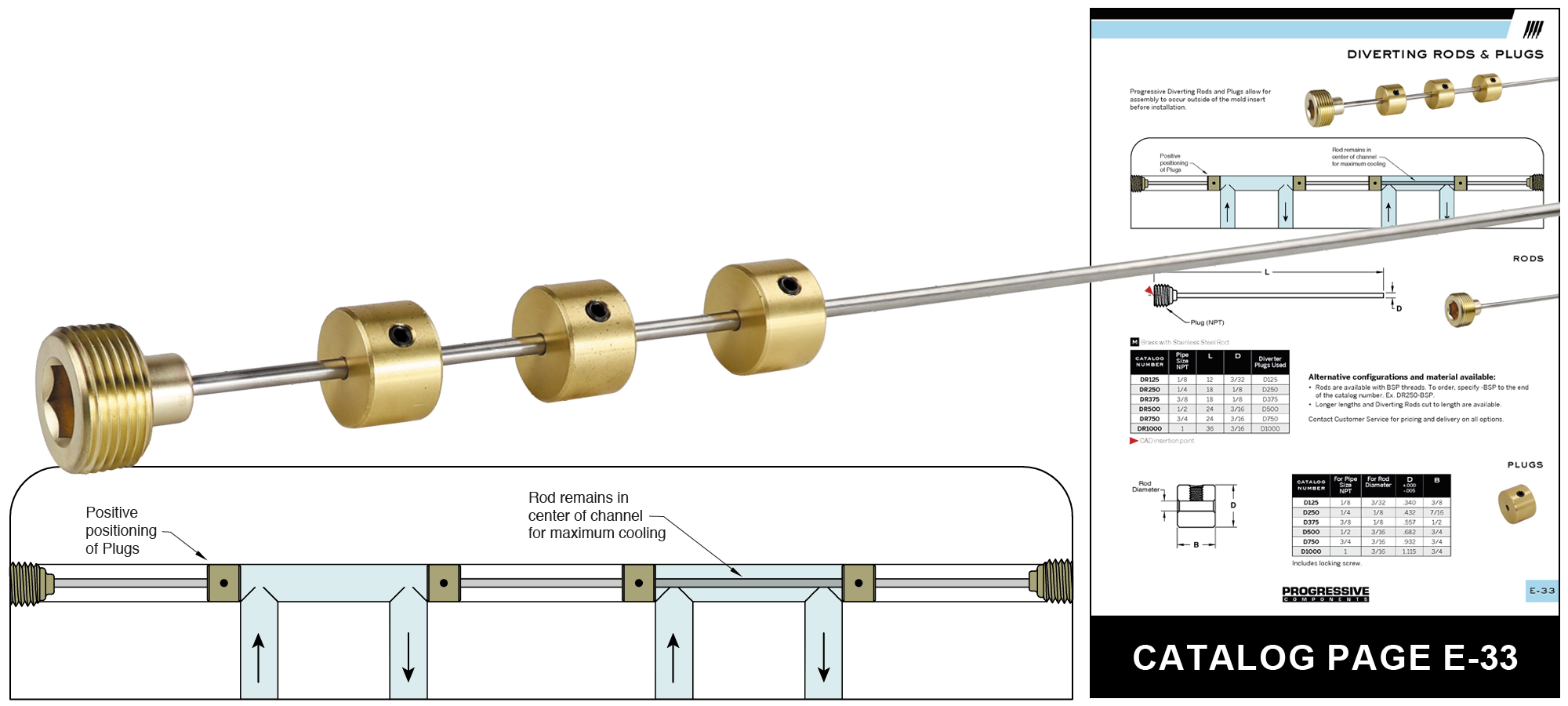

DIVERTING RODS AND PLUGS

Diverting Rods and Plugs allow for assembly to occur outside of the mold insert before installation.

Click HERE to view our recent press release.

For questions and more information on any of the products listed above: